strict management, quality first, quality service, and customer satisfaction

You know, in the oil and gas world, managing sediment properly really makes all the difference. It’s key to keeping things running smoothly and making sure equipment doesn’t wear out too quickly. These days, high-quality Cyclone Desanders have kinda become essential tools—they do a great job of trapping those tiny particles and keeping fluid treatment on point. If you’ve been following the industry news, you probably noticed that the global market for cyclone separators is expected to grow around 5.5% annually between 2021 and 2026. That just shows how much more companies need advanced separation tech. Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. is definitely leading the charge here, constantly working on new cyclone products that boost filtration efficiency and are super reliable. By always pushing for improvements and embracing new tech, they’re playing a big role in advancing sediment management. Honestly, high-quality Cyclone Desanders are pretty critical in industrial settings—they really make a difference.

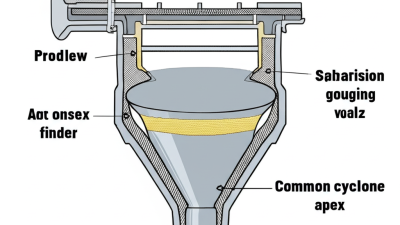

Cyclone desanders are pretty clever devices designed to make sediment control in industrial settings a whole lot easier. These high-quality tools use centrifugal force to separate out particles from fluids efficiently, so you’ll find them pretty essential in industries like oil and gas or wastewater treatment. They help keep the fluid clear and even reduce wear and tear on the equipment that comes after, which means smoother operations and some real cost savings down the line.

Cyclone desanders are pretty clever devices designed to make sediment control in industrial settings a whole lot easier. These high-quality tools use centrifugal force to separate out particles from fluids efficiently, so you’ll find them pretty essential in industries like oil and gas or wastewater treatment. They help keep the fluid clear and even reduce wear and tear on the equipment that comes after, which means smoother operations and some real cost savings down the line.

One thing I really like about top-notch cyclone desanders is their ability to handle all kinds of sediment sizes and amounts. They’re built tough, so they last through tough environments and keep performing reliably. Plus, they don’t need a ton of maintenance, which is a huge plus because then industries can focus on what they do best without constantly fussing over the sediment removal process. The latest materials and smart design features just make these desanders even better at what they do, making them a go-to choice for managing sediments in all kinds of industrial setups.

When it comes to dealing with industrial sediment, cyclone desanders are really starting to stand out as a better option compared to the old-school methods. Unlike those traditional approaches that mainly depend on gravity settling or filtration, cyclone desanders use centrifugal force to separate solids from liquids much more effectively. Honestly, this technology not only does a great job at separating, but it also takes up less space—so you can fit it into tighter spots in your plant without a fuss.

Pro tip: If you're thinking about upgrading to cyclone desanders, take a moment to understand the specific sediment you're dealing with. Knowing the particle sizes can make a big difference in picking the right system and getting the best results.

Plus, these systems are built to be pretty tough and require minimal maintenance, which really saves money over time. On the flip side, old-fashioned methods often need more frequent upkeep and can cause downtime, bumping up your long-term costs. Switching to cyclone desanders means you'll get better sediment handling and smoother operations—no more constant interruptions.

Another tip: Make sure to set up a regular schedule for monitoring and maintaining your cyclone desander. Keeping it in good shape means it’ll last longer and work better, letting you enjoy all the advantages of this advanced tech.

Lately, cyclone desanders are really gaining recognition for how well they manage industrial sediments. Honestly, they pack quite a few advantages that make a big difference across different applications. They’re pretty good at separating particles from fluids efficiently, which means less downtime and less fuss with maintenance — something that’s super important, especially in sectors like oil and gas. These devices work on centrifugal force, so they can handle high flow rates and keep performing consistently, even when the going gets tough. That kind of efficiency isn’t just about boosting productivity; it also helps keep the processes running smoothly by stopping sediment from piling up in the system.

Here at Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we totally get how crucial high-quality separation and filtration tools are for the oil and gas world. We’re always working on cutting-edge cyclone separation tech to give our clients the best. By constantly improving what we offer, we help operators better manage sediments, cut down on environmental impacts, and reduce operational costs. It’s all about making sure we’re a reliable partner in streamlining your industrial processes with our top-notch cyclone desanders.

High-quality cyclone desanders are really game-changers when it comes to managing industrial sediments. They do a great job at separating solid particles from liquids, which means less sediment piling up to deal with later. Honestly, using one of these devices can save a ton of money because you won't need to go for expensive dredging or disposal processes as often. It’s like hitting two birds with one stone — better operations and better savings.

And here’s the thing: these cyclone desanders don’t just help save money, they make your whole system run smoother. They keep the flow steady and make the water clearer, which is a huge plus. Plus, by getting rid of sediments effectively, they protect your downstream equipment from getting damaged or worn out too soon. That means fewer repairs and replacements, which is always a win. Overall, they help you use your resources more wisely, so you get more bang for your buck. As more companies are looking to be eco-conscious these days, investing in stuff like cyclone desanders isn’t just smart financially — it’s also a step toward being kinder to our environment.

Cyclone desanders are really changing the game when it comes to managing industrial sediment, especially in terms of how they help the environment. These nifty devices do a great job of separating out sediment from water — and they do it without relying on any nasty chemicals, which is pretty cool. From what industry reports are saying lately, using top-notch cyclone desanders can cut water treatment costs by up to 30%. Plus, they help reduce the environmental impact of industrial processes. It’s all part of the broader push across different sectors to adopt more sustainable practices, particularly now when climate change and crazy weather events like typhoons are becoming more common.

**Pro tip:** When you're choosing a cyclone desander, look for ones built with advanced materials that can handle corrosive environments. That way, they’ll last longer and stay efficient for a good while.

With natural disasters like tropical cyclones on the rise, it’s more important than ever to have solid sediment management solutions in place. Research shows that stronger storms are really taking a toll on coastal ecosystems, which in turn threatens agriculture and water quality. By bringing cyclone desanders into the picture, industries can not only run more smoothly but also help boost the resilience of local ecosystems against the wild weather that seems to be the new normal these days.

| Benefit | Description | Impact on Sustainability | Estimated Savings (%) |

|---|---|---|---|

| Sediment Removal Efficiency | High quality cyclone desanders effectively separate sediments from water. | Reduces the load on water treatment facilities, improving overall system efficiency. | 25% |

| Water Conservation | Recovers clean water for reuse in industrial processes. | Decreases fresh water consumption, promoting sustainable water management. | 30% |

| Reduction of Chemical Use | Minimizes the need for chemicals used in sediment treatment. | Lowers the environmental footprint associated with chemical manufacturing and disposal. | 20% |

| Operational Efficiency | Enhances the performance of wastewater systems. | Improves overall system longevity and reduces energy consumption. | 15% |

| Compliance with Regulations | Helps meet local and national environmental standards. | Promotes corporate responsibility and environmental stewardship. | 10% |

Lately, using top-quality cyclone desanders has really become a game-changer for managing sediments across different industries. Take Empaques del Cauca S.A. as an example — they've shown just how powerful cyclone separators can be when it comes to controlling tiny particles during the fique bag-making process. In fact, they achieved an impressive efficiency of anywhere from 66% up to 99% for particles between 1 and 10 micrometers. That’s a huge difference in cutting down sediment and boosting air quality around the plant.

Also, the materials used to build these cyclones matter a lot. Turns out, stainless steel just outperforms black steel—it's tougher and holds up better under different working conditions. Choosing the right materials, along with how well these cyclone desanders work overall, really highlights how important they’re becoming in industries that need to keep sediment in check. This is especially true when dealing with pollution from urban runoff or stormwater. By bringing in these kinds of tech, companies aren’t just making their operations smoother — they’re actually helping out the environment too. Pretty cool, right?

: Cyclone desanders are used for effectively managing industrial sediment by separating particles from fluids, which helps minimize downtime and maintenance requirements.

They operate on centrifugal force principles, allowing them to handle high flow rates and provide consistent performance, which enhances productivity and prevents sediment buildup.

Cyclone desanders enhance sustainability by separating sediment from water without harmful chemicals, potentially reducing water treatment costs by up to 30% while minimizing the ecological footprint.

By integrating cyclone desanders into sediment management strategies, industries can improve operational efficiency and help protect local ecosystems from the adverse effects of climate change.

It's important to consider cyclone desanders made with advanced materials that can withstand corrosive environments, which extends their lifespan and efficiency.

Regular maintenance ensures optimal performance and maximizes the sustainability impact of cyclone desanders, enabling them to operate effectively over time.

High-quality cyclone desanders really play a crucial role when it comes to managing industrial sediments better. They’re packed with advanced tech that’s way beyond the old-school methods of controlling sediments. Basically, these devices do a great job at separating sediments from liquids, so industries can keep things clean and run smoothly without a hitch. When you compare cyclone desanders to more traditional approaches, it’s pretty clear they deliver better performance and efficiency — it’s like night and day.

Switching to top-notch cyclone desanders doesn’t just make sediment management simpler; it can also save companies a good chunk of money and even be better for the environment. Companies like Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. are leading the charge here, constantly improving their separation tech to meet the tough demands of the oil and gas world. The evidence from case studies shows that firms using these high-quality systems see their operations get more sustainable, with lower costs all around. Honestly, cyclone desanders are really transforming the way industries handle sediments — making everything more efficient and eco-friendly in the process.