strict management, quality first, quality service, and customer satisfaction

You know, in the fast-changing world of water treatment tech, there's been a real uptick in how much folks need reliable sand removal solutions, especially in the oil and gas scene. I read a recent report from Global Market Insights, and it predicts the desander market’s really going to take off — with an expected annual growth rate of about 6.5% up until 2026. It’s mostly because everyone’s looking for better filtration gear to keep things running smoothly and cut down on downtime.

As Dr. John Mason, an expert in separation tech, puts it, 'Using advanced desander systems is pretty much essential for keeping production up and protecting your equipment.' At Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we’re all about pushing the boundaries with innovative cyclone separation products and filtration tech that actually meet these industry needs. We’re constantly working on improvements — not just to make desanders more effective but also to tackle the real challenges in water treatment, all with an eye on building a sustainable future for oil and gas operations.

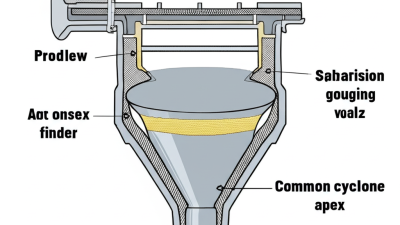

In the realm of water treatment, effective sand removal is crucial for maintaining system efficiency and prolonging equipment lifespan. This has led to the emergence of innovative desander technologies that redefine how sand and particulate matter are managed in water systems. One noteworthy advancement is the use of hydrocyclones, which employ centrifugal force to separate sand from water. These devices are not only efficient but also minimize energy consumption, making them an eco-friendly choice for water treatment facilities.

Another promising technology is the use of automated self-cleaning filters. These systems continuously remove sand and other debris without manual intervention, significantly reducing downtime and labor costs. Additionally, some solutions integrate real-time monitoring systems, which help in optimizing the operation based on varying water quality conditions. By adopting these innovative desander technologies, water treatment facilities can enhance their operational efficiency, ensuring cleaner water output and compliance with environmental regulations. The ongoing advancements in desander solutions signify a pivotal shift towards more effective and sustainable practices in water management.

| Desander Technology | Efficiency (%) | Flow Rate (m³/h) | Maintenance Frequency (Months) | Power Consumption (kW) |

|---|---|---|---|---|

| Hydrocyclone Desander | 90 | 50 | 12 | 15 |

| Vortex Separator | 85 | 60 | 10 | 18 |

| Gravity Sand Filter | 75 | 40 | 8 | 10 |

| Disc Filter | 88 | 70 | 6 | 20 |

| Sand Bed Filtration | 80 | 55 | 9 | 12 |

| Coalescing Plate Separator | 92 | 75 | 7 | 22 |

| Screw Sand Separator | 87 | 45 | 11 | 16 |

| Centrifugal Sand Separator | 90 | 80 | 5 | 25 |

| Bag Filter | 76 | 30 | 6 | 8 |

| Hydraulic Desander | 89 | 65 | 4 | 30 |

When selecting the best desander solutions for efficient sand removal in water treatment, there are several key features that should be prioritized. Firstly, the design and construction materials of the desander are crucial. Look for models that utilize durable materials such as stainless steel or high-density polyethylene, which can withstand harsh conditions and resist corrosion. Efficient flow dynamics is another critical aspect; a well-engineered desander will optimize the separation process, ensuring that sand and sediment are effectively removed while minimizing pressure loss.

In addition to the physical characteristics, operational efficiency and maintenance requirements are equally important. Opt for desanders that offer easy access for cleaning and maintenance, reducing downtime and operational costs. Evaluate the ability to handle varying flow rates, as flexibility in performance can enhance the desander’s effectiveness in different water treatment scenarios. Advanced monitoring features, such as pressure sensors and flow meters, can also provide real-time data, allowing operators to maintain optimal performance and respond promptly to any issues that may arise.

In the realm of water treatment, the efficient removal of sand is paramount to maintaining the integrity and functionality of systems. A comparative analysis of leading desander models reveals significant advancements designed to tackle the challenges associated with sand removal. These innovative solutions vary in design and technology, providing users with several effective options to mitigate the impacts of sand buildup. By focusing on factors such as flow rate, durability, and ease of maintenance, facilities can select the desander model that best suits their operational needs.

Recent environmental concerns, particularly in Southeast Asia, highlight the dire consequences of inadequate sand management. Reports indicate that intensive sand mining threatens critical ecosystems, drawing attention to the importance of sustainable sand removal practices. Such developments emphasize the need for reliable desander solutions that not only improve water treatment efficiency but also contribute to the preservation of vital natural resources. As industries adapt to these challenges, the role of advanced desander technology becomes increasingly crucial in promoting a balance between operational efficiency and environmental protection.

In the realm of water treatment, selecting an effective desander solution is crucial for optimizing system performance while maintaining cost-efficiency. Various desander technologies offer different mechanisms for sand removal, each carrying its own implications for operational costs. For instance, cyclone separators, known for their high efficiency in isolating particles using centrifugal force, can initially seem costly but often result in lower maintenance costs and extended equipment lifespan. This long-term financial advantage makes them a valuable investment for facilities processing large volumes of water.

Conversely, simpler systems such as gravity sand separators might have lower upfront costs but can incur higher operational expenses due to less effective sand removal and more frequent maintenance needs. The choice between these options hinges on a facility's specific requirements, including the volume of water treated, the concentration of suspended solids, and the overall budget. By analyzing the total cost of ownership, including installation, maintenance, and energy use, water treatment facilities can make informed decisions that align both effectiveness and cost-effectiveness in their desander solutions.

In the realm of water treatment, the effectiveness of desander solutions is crucial for efficient sand removal. User reviews and real-world performance data indicate that the best desanders significantly minimize downtime and maintenance costs while enhancing water quality. For instance, a recent analysis highlighted that systems equipped with advanced filtration technologies achieved up to a 30% reduction in particulate matter in treated water, underscoring their operational efficacy. Users reported lower operational costs due to decreased clogging and maintenance frequency, which can translate into savings of around 20% annually.

Moreover, real-world performance tests showcase a notable correlation between desander design and efficiency. Systems with modular designs that allow for easy upgrades and maintenance have garnered praise for their reliability under varying flow conditions. Feedback from industry professionals reveals that desanders offering automated monitoring features not only improve operational efficiency but also provide critical data that can optimize maintenance schedules. These insights provide valuable benchmarks for choosing the right desander solution, ensuring that water treatment facilities meet both regulatory standards and operational goals efficiently.

In recent years, the water treatment industry has witnessed a pivotal shift towards enhanced desander technologies, aiming for improved efficiency in sand removal. Notably, a report by Research and Markets indicates that the global water treatment market is projected to grow at a CAGR of 7% from 2022 to 2030, highlighting the increasing demand for advanced filtration solutions. This growth emphasizes the need for innovative desanding methods that not only facilitate sand removal but also ensure increased longevity and reduced operational costs.

Emerging trends in desander development include the integration of automated systems and smart technologies. For instance, the adoption of Internet of Things (IoT) devices for real-time monitoring can significantly enhance operational efficiency by allowing water treatment facilities to optimize their processes based on live data. According to a study published by the International Journal of Environmental Research, facilities employing smart desanders reported a 25% reduction in maintenance costs and a 30% improvement in process efficiency. Such advancements underscore a future where desanders are not only effective in maintaining water quality but also contribute to the overall sustainability of water management practices.

: It is recommended to choose desanders made from durable materials like stainless steel or high-density polyethylene, as they can withstand harsh conditions and resist corrosion.

Efficient flow dynamics optimize the separation process, ensuring effective removal of sand and sediment while minimizing pressure loss.

When evaluating operational efficiency, consider desanders that provide easy access for cleaning and maintenance, as this can reduce downtime and lower operational costs.

Desanders that can handle varying flow rates offer flexibility in performance, enhancing their effectiveness for different water treatment scenarios.

Look for desanders equipped with advanced monitoring features such as pressure sensors and flow meters. These provide real-time data to maintain optimal performance and quickly respond to issues.

User reviews indicate that the best desanders can significantly minimize downtime and maintenance costs while enhancing water quality, achieving up to a 30% reduction in particulate matter in treated water.

Using effective desanders can lead to lower operational costs due to decreased clogging and maintenance frequency, translating into potential savings of approximately 20% annually.

Modular designs that allow for easy upgrades and maintenance are preferred, as they have proven to be reliable under varying flow conditions.

Automated monitoring features improve operational efficiency and provide critical data that can help optimize maintenance schedules in desander operations.

The article "10 Best Desander Solutions for Efficient Sand Removal in Water Treatment" explores the top innovative desander technologies designed to enhance water treatment processes. It highlights key features to consider when selecting the best desander solutions, including efficiency, durability, and ease of maintenance. A comparative analysis of leading desander models showcases their effectiveness in sand removal, while a discussion on cost-effectiveness evaluates different solutions for optimal budget management. User reviews add a practical perspective on real-world performance, underscoring the importance of reliable desander equipment in operational settings.

In light of advancements in the field, future trends in desander development indicate a shift toward more efficient and sustainable technologies. As a leader in separation equipment, Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. is at the forefront of these innovations, focusing on enhancing cyclone separation products and ensuring effective water treatment in the oil and gas industry. This commitment positions the company to meet the evolving needs of its clients for high-performance desander solutions.