strict management, quality first, quality service, and customer satisfaction

You know, when it comes to making water treatment more efficient, the Hydrocyclone Separator has really become a game-changer in the oil and gas industry. I came across a recent report by Global Industry Analysts Inc., and it said that the market for these separators is expected to hit around $1.5 billion by 2026. That’s a pretty solid sign that folks are really banking on advanced separation tech nowadays. It’s actually quite impressive to see how much Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. is pushing the envelope here—constantly developing new, cutting-edge cyclone products to keep up with what the industry needs.

You know, when it comes to making water treatment more efficient, the Hydrocyclone Separator has really become a game-changer in the oil and gas industry. I came across a recent report by Global Industry Analysts Inc., and it said that the market for these separators is expected to hit around $1.5 billion by 2026. That’s a pretty solid sign that folks are really banking on advanced separation tech nowadays. It’s actually quite impressive to see how much Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. is pushing the envelope here—constantly developing new, cutting-edge cyclone products to keep up with what the industry needs.

I also read what Dr. John Tanner, a well-known expert in hydrocyclones, had to say. He mentioned, “Hydrocyclone Separators don’t just boost efficiency—they also cut down on waste big time, which makes them a must-have in modern water treatment setups.” That really rings true with the way Shanghai Shangjiang is dedicated to improving filtration and separation processes. They’re always working on delivering high-quality solutions that help companies run smoother and more efficiently. As the industry keeps evolving, I have no doubt that these improved hydrocyclone techs will keep setting the bar high for water treatment in oil and gas—that’s pretty exciting, don’t you think?

Hydrocyclone separators play a crucial role in maximizing the efficiency of water treatment processes by enhancing solid-liquid separations while minimizing energy consumption. Recent studies focused on optimizing hydrocyclone designs, particularly those featuring innovative overflow slit structures, showcase significant advancements. These experiments and numerical simulations have demonstrated that such modifications can effectively reduce the energy requirements during the separation process, which has been a longstanding concern in hydrocyclone applications.

Hydrocyclone separators play a crucial role in maximizing the efficiency of water treatment processes by enhancing solid-liquid separations while minimizing energy consumption. Recent studies focused on optimizing hydrocyclone designs, particularly those featuring innovative overflow slit structures, showcase significant advancements. These experiments and numerical simulations have demonstrated that such modifications can effectively reduce the energy requirements during the separation process, which has been a longstanding concern in hydrocyclone applications.

Moreover, the integration of customized water clarifiers complements hydrocyclone technology by further improving recovery rates and ensuring compliance with stringent discharge regulations. By decreasing the concentration of oil in water through the use of production chemicals, these clarifiers enhance waste management practices and contribute to a more sustainable water treatment approach. As industries continue to seek efficient and environmentally friendly solutions, the synergy between advanced hydrocyclone designs and tailored clarification systems will undoubtedly lead to better performance outcomes in water treatment.

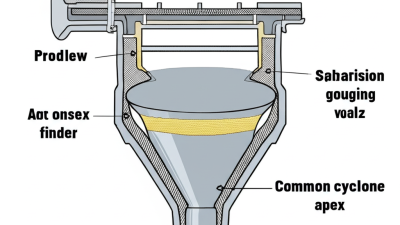

The operational parameters of hydrocyclone separators are crucial for optimizing performance in water treatment processes. Key factors such as feed flow rate, inlet pressure, and particle size distribution significantly influence separation efficiency. A balanced feed flow rate ensures consistent performance, while adjustments in inlet pressure can enhance the centrifugal forces acting on the particles. This is particularly important for achieving optimal separation of solids from liquids, which is essential in various applications, including wastewater treatment and mineral processing.

Furthermore, understanding the effects of hydrocyclone geometry—such as the diameter of the inlet and the cone angle—plays a vital role in enhancing operational performance. Different configurations can be tailored to specific applications, allowing for better handling of varying solids concentrations. Regular monitoring and fine-tuning of these parameters can lead to significant improvements in separation efficiency, ultimately resulting in reduced operational costs and improved sustainability in water treatment systems. By leveraging these insights, facilities can ensure that their hydrocyclone separators operate at peak performance, delivering effective and efficient solutions for water treatment challenges.

The comparative analysis of hydrocyclones versus traditional water treatment methods reveals significant advantages for hydrocyclone technology. Hydrocyclones utilize a swirling centrifugal process to separate oil and water based on their density differences, as supported by recent numerical simulations and experimental studies. This mechanism not only enhances separation efficiency but also reduces the footprint of water treatment systems, making hydrocyclones an increasingly popular choice in the oil and gas industry.

Tips for optimizing the use of hydrocyclones include adjusting the inlet velocity for improved performance. Experimental data suggest that variations in the inlet velocity can directly impact the effectiveness of oil-water separation. Additionally, regular maintenance and performance monitoring can help maintain operational efficiency and extend the life of the equipment.

At Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we are dedicated to advancing hydrocyclone technology through continuous research and development. Our focus on delivering innovative separation solutions aligns with the industry's growing demand for efficient, cost-effective water treatment methods. By embracing these advancements, industries can enhance their operational efficiencies and achieve better environmental compliance.

The hydrocyclone separator technology has become a pivotal solution in modern water treatment processes, particularly in enhancing sediment removal efficiency. Recent studies indicate that tailored hydrocyclone designs can significantly optimize the separation of solid particles from liquids. For instance, a report by the American Water Works Association highlighted that custom-designed hydrocyclones can achieve sediment removal efficiencies exceeding 90%, compared to traditional sedimentation methods which typically max out around 60-70%.

Several design parameters influence the performance of hydrocyclones, including the inlet geometry, cone angle, and vortex finder length. Adjustments to these factors can lead to notable improvements in sedimentation rates. An industry analysis showed that hydrocyclones with an optimally calculated inlet geometry reduce turbulence and promote a more efficient flow pattern, facilitating better solid-liquid separation. Such refinements can increase the overall throughput of water treatment facilities while lowering operational costs.

Furthermore, comparative studies demonstrate that using a multi-stage hydrocyclone system can further enhance the effectiveness of sediment removal processes. Reports indicate that with a two or three-stage configuration, sediment removal efficiencies can reach upwards of 95%, making hydrocyclones a vital tool in achieving higher water quality standards while addressing the growing challenges of water resource management.

Hydrocyclones have emerged as a pivotal technology in the realm of municipal water treatment, streamlining processes and enhancing efficiency. Case studies illustrate their effectiveness in separating solid particles from water, significantly improving treatment outcomes. For instance, a recent report highlighted that incorporating hydrocyclones can achieve up to 90% removal efficiency of suspended solids, thereby reducing the load on downstream filtration systems. This points to the potential for cost-saving in operational expenses while enhancing overall water quality.

Moreover, advancements in cyclone-integrated systems are revolutionizing the landscape of water treatment. Research indicates that these systems not only improve the capture of microfibers during various processes but also maintain optimal flow rates, which is crucial for large-scale applications like municipal treatment plants. Furthermore, studies on vortex aeration have shown promising results in enhancing aeration efficiency, further contributing to sustainable wastewater treatment practices. These innovations collectively underline the importance of hydrocyclone technology in addressing contemporary challenges in water treatment and management.

Hydrocyclone separators have become an indispensable technology in water treatment processes, particularly within the oil and gas industry. By leveraging centrifugal force, these devices efficiently separate solid particles from liquids, enhancing operational efficiency. Industry metrics indicate that hydrocyclones can achieve separation efficiency rates exceeding 90%, significantly outperforming traditional filtration methods. This level of performance not only improves water quality but also reduces downtime and operational costs.

Recent reports highlight that integrating hydrocyclone technology can lead to a reduction in the volume of waste by up to 50%, underscoring its effectiveness in managing water treatment challenges. Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. remains at the forefront of this innovation, constantly refining cyclone separation products and technologies to meet the evolving demands of the industry. The company's commitment to excellence positions it as a key player in enhancing the performance of hydrocyclones, thereby ensuring that clients achieve optimal treatment outcomes. Through continuous development and rigorous assessment of industry metrics, Shangjiang contributes to elevating operational standards in water treatment processes.

| Metric | Value | Unit | Comments |

|---|---|---|---|

| Separation Efficiency | 90 | % | Effectiveness in removing solids |

| Operating Pressure | 2.5 | bar | Optimal pressure for performance |

| Feed Flow Rate | 100 | m³/h | Hourly inflow into the system |

| Cut Size | 50 | µm | Particle size separation threshold |

| Maintenance Interval | 6 | months | Frequency of required service |

| Energy Consumption | 5 | kWh/m³ | Energy efficiency in operation |

: Hydrocyclones are primarily used to separate solid particles from liquids, enhancing sediment removal efficiency in water treatment processes.

Custom-designed hydrocyclones can achieve sediment removal efficiencies exceeding 90%, while traditional sedimentation methods typically max out around 60-70%.

Key design parameters include inlet geometry, cone angle, and vortex finder length, which can be adjusted to improve sedimentation rates.

A two or three-stage configuration can enhance sediment removal efficiencies to upwards of 95%, making them more effective in water treatment.

Hydrocyclones can achieve up to 90% removal efficiency of suspended solids, reducing the load on downstream filtration systems and leading to cost savings in operational expenses.

These systems improve the capture of microfibers and maintain optimal flow rates, crucial for large-scale municipal treatment applications.

Hydrocyclones can achieve separation efficiency rates exceeding 90%, reduce waste volume by up to 50%, and improve operational efficiency in water treatment processes.

The company is recognized for continuously refining cyclone separation products and technologies to enhance the performance of hydrocyclones and meet evolving industry demands.

Vortex aeration enhances aeration efficiency, contributing to more sustainable wastewater treatment practices alongside hydrocyclone use.

The article "Unlocking Efficiency in Water Treatment with Hydrocyclone Separator Technology Insights and Performance Data" explores the significant role of Hydrocyclone Separators in enhancing water treatment processes. It begins by discussing how these separators can maximize efficiency by effectively removing sediments and impurities from water, thus outperforming traditional treatment methods. The understanding of operational parameters is crucial for achieving optimal performance, and the comparative analysis highlights their advantages over conventional techniques.

Furthermore, the article delves into the impact of Hydrocyclone design on sediment removal efficiency, supported by real-world case studies in municipal water treatment applications. It concludes by outlining key industry metrics for assessing the effectiveness of Hydrocyclone Separators, showcasing their potential in revolutionizing water treatment practices. With a focus on continuous development and improvement in cyclone separation technology, Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. aligns with these insights, emphasizing their commitment to advancing separation and filtration equipment for various industries, including oil and gas.