strict management, quality first, quality service, and customer satisfaction

In the fast-changing world of oil and gas, the way hydrocyclone liners perform really matters when it comes to getting those separation processes just right. I’ve come across reports that show if the liners aren’t up to par, it can seriously hit productivity — we're talking about losses of up to 15% of output. At Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we get how crucial it is to push forward with new ideas in hydrocyclone liner tech to tackle these issues head-on. We’re dedicated to creating better separation and filtration equipment, specifically designed for the industry’s needs. Looking ahead, it’s clear that focusing on improving liner materials and design is key — because that’s how we’ll boost performance, cut costs, and keep things running smoothly and reliably in the field.

Hydrocyclone liners are pretty essential when it comes to boosting the efficiency of solid-liquid separation in all sorts of industrial setups. You know, a bunch of things can really affect how well these liners work—things like the wear resistance of the material, how the flow moves through the system, and the actual design of the liner itself. From the latest industry chatter, it turns out that over 30% of the downtime in mineral processing plants is due to hydrocyclone performance issues, often tied back to liners not doing their job properly. So, getting a handle on what influences liner efficiency is key if you wanna keep things running smoothly and get the most out of your processes.

If you're looking to boost your hydrocyclone liner game, here are a couple of tips. First off, go for liners made from really tough, wear-resistant materials—stuff like polyurethane or ceramic composites. They last longer and help keep the flow just right. Also, make it a habit to keep an eye on your operating parameters—things like pressure and slurry density—and tweak them to fit what you're processing. Doing this stuff proactively can really up your recovery rates and make your whole operation more efficient. There are even case studies out there showing that when you optimize liner strategies, performance can jump by around 15%.

And don’t forget, regular inspections and maintenance are super important. Catching early signs of wear or problems with the design means you can replace liners before things go really wrong. Setting up a scheduled replacement plan based on actual performance data has been shown to cut down on unexpected shutdowns and boosts the reliability of your hydrocyclone system. Overall, focusing on these areas can seriously improve how well your liners perform and, in turn, give your productivity a nice little boost.

In the world of industrial processes, hydrocyclones are pretty much essential for separating stuff out. But, let’s be honest, operators often face some common hurdles that can really mess with how well these systems work. One biggie is the wear and tear on the liners — over time, they can get battered, leading to early failure and a drop in performance. Picking the right material for these liners is super important; cheap or low-quality materials tend to wear out faster, which means you’re constantly replacing them and that can get pretty costly and frustrating.

Another tricky part is correctly adjusting the feed parameters. Small changes in flow rate or particle size can have a big impact on how well the separation actually happens. If the feed isn’t spot-on with what the hydrocyclone needs, you might end up with less-than-perfect results — like lower product quality or higher energy bills. The key here is regular monitoring and maintenance. Using real-time data analytics can be a game-changer, helping operators tweak things just right to keep everything running smoothly and extend the life of those liners in all kinds of industrial setups.

Hydrocyclones are pretty important in a lot of industrial setups, especially when it comes to making solid-liquid separation more efficient. Keeping the liners in these machines in good shape is super crucial if you want them to work well and last a long time. Lately, experts have been emphasizing some key practices—like regularly checking flow rates and tweaking the design based on what the specific job needs. Paying attention to these little details can really make a difference, and some studies even suggest ways to fine-tune these units so they hit the right performance targets and fit operational goals.

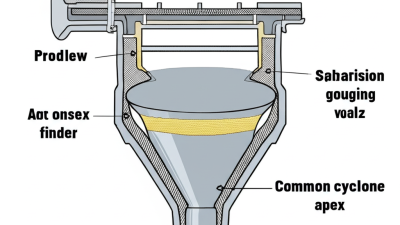

On top of that, new tech breakthroughs are showing a lot of promise, especially in how we separate tiny particles. For example, in cleaning up soil contaminated with heavy metals, newer hydrocyclone designs have managed to achieve separation efficiencies over 89%. Things like properly setting the vortex finder length and getting the right cylinder-to-cone ratio really do affect how well everything works overall. By sticking to these best practices and constantly refining hydrocyclone designs, industries can get better at their processes and tackle common issues with liners more effectively.

| Maintenance Practices | Impact on Liner Performance | Frequency of Maintenance | Common Issues Addressed | Recommended Tools |

|---|---|---|---|---|

| Visual Inspection | Identifies wear and tear | Weekly | Cracking, Erosion | Inspection Camera |

| Replacement Scheduling | Ensures optimal efficiency | Monthly | Blockages | Liner Replacement Kit |

| Performance Testing | Detects inefficiencies | Quarterly | Flow Rate Loss | Flow Meter |

| Cleaning Procedures | Reduces buildup | Bi-Weekly | Accumulation of debris | High-Pressure Washer |

| Wear Measurement | Monitors material loss | Annually | Material fatigue | Thickness Gauge |

Hydrocyclones are pretty vital in the oil and gas industry—they’re basically the workhorses when it comes to sorting out different fluids and solids. But, honestly, getting these things to work at their best isn’t always straightforward. At Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we get it—things like the liner material and the shape of the cyclone can really make or break performance. That’s why we put a lot of focus on tweaking these design aspects, to make sure our hydrocyclones do their job as efficiently as possible.

We’re constantly pushing to improve cyclone technology. A big part of that is designing liners that are tougher and better at flowing smoothly. By using new, high-tech materials and fine-tuning the shape of the cyclone itself, we’re able to boost how well it separates stuff and also cut down on maintenance costs. These innovations aren’t just for us—they help our clients get more out of their operations and make the whole oil and gas extraction process more sustainable. It’s all about making sure we’re doing our part in a pretty competitive industry, and honestly, it’s pretty exciting to be part of that progress.

When it comes to industrial applications, making hydrocyclones more efficient is pretty much essential for getting the best separation results. I came across a recent case in the mining world that really shows how a few targeted upgrades can make a big difference. They swapped out standard polyurethane liners for high-performance ceramic ones, and guess what? They saw about a 30% boost in separating those tiny particles. Not only did this cut down on waste, but it also improved the overall quality of the product. It’s pretty much in line with what the Industrial Minerals Association reports—they mentioned that using more advanced, wear-resistant materials can slash operating costs by up to 15%. Pretty impressive, right?

On a different note, there’s also a wastewater treatment plant that totally redesigned their hydrocyclone system, focusing on the liner shape and the materials they used. Thanks to some fancy CFD simulations—yeah, computational fluid dynamics—they were able to fine-tune the flow inside, which resulted in about a 25% drop in downtime. This kind of upgrade doesn’t just boost how much they can process, but it also makes their liners last way longer. All in all, these examples really highlight how investing in better materials and smarter design can make a real difference in operational efficiency and durability.

: Hydrocyclone liners are components that enhance the efficiency of solid-liquid separation in industrial processes. They are crucial as their performance significantly impacts the overall efficiency of hydrocyclones, affecting operations such as mineral processing.

Advanced wear-resistant materials such as polyurethane or ceramic composites are recommended. These materials not only extend the life of the liners but also maintain optimal flow characteristics.

Operators should regularly monitor and adjust parameters like pressure and density to align with the specific characteristics of the slurries being processed, leading to improved recovery rates and processing efficiency.

Common challenges include wear on the liners, which can lead to premature failure, and improper feed parameter adjustments, such as variations in flow rate and particle size distribution, impacting separation efficiency.

Real-time data analytics can help operators monitor performance and make informed adjustments to optimize hydrocyclone efficiency, prolonging the lifespan of liners and improving separation processes.

Regular maintenance and inspections are crucial to identify early signs of wear or design flaws. A scheduled replacement cycle based on real-time performance data can also reduce operational disruptions.

Optimization can be achieved by focusing on innovative liner designs, using advanced materials, and improving the geometric shape of the hydrocyclone to enhance flow dynamics and reduce wear.

Using subpar materials can increase wear rates, affect the hydrocyclone's operational lifespan, and necessitate more frequent replacements, ultimately undermining process efficiency.

Enhanced efficiency leads to improved separation performance, increased productivity, reduced maintenance costs, and overall better quality of the processed products in industries like oil and gas.

Proper alignment ensures that the desired separation is achieved, preventing issues such as poor product quality and increased energy costs, which can arise from mismatched feed parameters.

When it comes to the oil and gas industry, getting hydrocyclone liners dialed in just right is a big deal if you want the separation processes to work smoothly. In this post, I’ll walk you through some of the key factors that impact how well these liners perform, and I’ll be honest—there are quite a few operational hiccups that folks encounter in the field. We’ll also chat about some practical tips for keeping those liners in tip-top shape, so your systems can run at their best.

Plus, I’ll share some ideas on how tweaking the design of the hydrocyclone itself can give you a real boost in efficiency. To back this up, there are a few case studies sprinkled in showing how other companies have managed to make big improvements in various setups. Here at Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we’re all about pushing the envelope with advanced separation tech. Our goal? To give your technicians and engineers the practical know-how they need to tackle these efficiency challenges head-on and keep things running smoothly.