strict management, quality first, quality service, and customer satisfaction

You know, in the ever-changing world of industrial filtration, Hydrocyclone Separators really stand out as a key innovation — especially in the oil and gas industry. I recently came across a market report by Research and Markets that says the global hydrocyclone market might hit around $1.4 billion by 2025. That’s mostly because demand for smarter, more efficient separation tech is picking up. Companies like Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. are really leading the charge here, developing advanced cyclone separation products that are specifically designed to meet industry needs. By using Hydrocyclone Separators, firms can boost their efficiency, cut down on downtime, and get more done overall.

In this article, I want to dive into how these separators are actually transforming industrial filtration — making resource extraction and processing so much better than before.

Hydrocyclone separators have really become a go-to technology in industrial filtration, especially in the oil and gas world. Basically, they use centrifugal force to separate out particles based on how dense they are — a pretty efficient way to get solids out of liquids. I read somewhere that, according to Grand View Research, the global market for hydrocyclones could hit around USD 600 million by 2027. That’s mainly because more folks are searching for better filtration options and wanna cut down on operational downtime.

At Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we get how important hydrocyclone technology is. We’re passionate about creating advanced separation and filtration equipment, and that’s helped us become a name you can trust in this space. We’re always working on improving our cyclone products so they keep up with what our customers need — giving top-notch performance and reliability. Hydrocyclones are pretty impressive, often filtering out over 90% of the particles, though this can vary depending on the application and how the system is designed.

A quick tip if you’re choosing a hydrocyclone for your process: think about things like flow rate, particle size, and specific gravity. Getting these settings right can really boost how well your filtration works and help save some cash. Also, don’t forget — regular maintenance is key. It helps prevent blockages and keeps everything running smoothly over time.

This chart illustrates the efficiency of hydrocyclone separators in various industrial applications, comparing the filtration efficiency percentage across different industries.

Hydrocyclone separators have really become a game-changer in industrial filtration, especially when it comes to efficiently sorting particles out of liquids. The magic behind how they work is based on centrifugal force — kind of like how a spinning top stays upright. This allows hydrocyclones to separate things quickly by taking advantage of the fact that solids and liquids have different densities. According to a report from Frost & Sullivan, industries that use hydrocyclones can often reach separation rates of over 90%, which not only cuts down on waste, but also boosts the overall quality of the final product. Honestly, the design of these devices really makes a difference—they’re built to make rapid separation easy and keep downtime to a minimum.

And there’s more good news — they can actually save companies a ton of money. The American Filtration Society did a study and found that switching to hydrocyclones can slash filtration costs by as much as 40%, compared to regular filters. This is mostly because they need fewer chemical additives and help recover valuable stuff like minerals and metals more efficiently. As more businesses look for greener, cost-effective options, hydrocyclones are really standing out as a smart choice to improve industrial filtration all around.

Hydrocyclone separators are really changing the game in industrial filtration. They help boost efficiency and cut down on operational costs—which is pretty awesome. But setting up these systems isn’t just plug-and-play; you’ve got to take it step by step to get the best results. First off, you want to really consider what your specific operation needs—like what kind of materials you’re sorting through and what kind of output quality you’re aiming for. That’ll help you pick the right hydrocyclone design and setup.

Pro tip: If you’re serious about making sure it works well, try running a pilot test with a single hydrocyclone unit first. This way, you can see how it performs in your actual environment and tweak things if needed before going all-in.

Once you’ve chosen the system, installation is the next step. Make sure it’s properly integrated with your existing machinery and workflows—don’t overlook this part! Regular maintenance and keeping an eye on performance is key to keeping everything running smoothly. Being aware of common wear and tear, and having a maintenance plan in place, can save you a lot of headaches down the line.

Another tip: Take the time to train your team on how to operate and maintain the hydrocyclone system. The more they know, the better your system will perform. Plus, involving your staff in this process really encourages a culture of continuous improvement and operational excellence—that’s how you get the most out of your investment.

Hydrocyclone separators have really become quite the buzz in industrial filtration these days, mainly because they do a pretty good job at separating particles and clarifying liquids. That said, they’re not perfect and come with their own set of challenges. One pretty common issue is sizing the hydrocyclone just right — get it wrong, and suddenly, you’re looking at less efficient separation and costs that go through the roof. I read in a report by the American Filtration Society that tweaking the size and dimensions of a hydrocyclone can boost its efficiency by about 20%. Honestly, it just shows how crucial it is to get the design right from the start.

Another thing to watch out for is maintenance — these things do take a beating, especially in abrasive environments. Over time, wear and tear can really pull down performance, with some studies suggesting efficiency might drop anywhere from 15% to 30%. Regular checks and using materials that are built to last can help keep things running smoothly. If industries take proactive steps to tackle these common issues, they can drastically improve how reliable and effective their hydrocyclone separators are for filtration. It’s all about staying ahead of the game and giving these units the care they need to do their job well.

Hydrocyclone separators have really started to shake things up in the world of industrial filtration. They're showing some pretty impressive advantages over more traditional methods like gravity filters and bag filters. I recently came across a report from the Filtration Society that mentioned hydrocyclones can often hit separation efficiencies of over 90%. That’s a big jump compared to the usual 60-70% you get with older, more conventional systems. The reason behind this boost? It’s mainly because hydrocyclones use centrifugal force — which means they can process stuff faster and don’t need as much maintenance as the old setups.

Oh, and here’s the kicker — operating costs tend to be way lower too. A study by the American Filtration Institute pointed out that hydrocyclones can cut down energy use by up to 40%. That’s because they don’t rely on super complicated machinery or a bunch of mechanical parts, which keeps things simple and efficient. Plus, with fewer breakdowns and less downtime, they really make life easier for industries trying to clean up their processes and save some cash in the meantime. As more companies put a big focus on sustainability and efficiency nowadays, switching to hydrocyclone technology isn’t just a good idea — it’s pretty much becoming essential for staying competitive down the road.

Hydrocyclone tech is really pushing the boundaries when it comes to transforming industrial filtration, especially in fields like agriculture and mining. As companies gear up to boost efficiency and get more out of their processes, newer hydrocyclone designs are stepping up and delivering better performance all around. Recent research shows that introducing hydrocyclones into filtration setups can bump up separation efficiency by as much as 90%. That’s a game-changer—it means less waste, lower energy use, and just more streamlined operations. This kind of upgrade is pretty crucial, especially in mining, which’s booming to meet the world’s ever-growing demand for raw materials.

Looking ahead, trends in hydrocyclone tech seem to point towards more automation and AI-powered systems. With real-time data analytics at your fingertips, companies can tweak and optimize their filtration processes on the fly, squeezing out even more productivity. For example, in Hong Kong, AI is expected to boost productivity across different sectors by around 20-30%. Embracing these high-tech solutions can really save costs and help operations run more smoothly.

When you're thinking about hydrocyclone setups, it’s a good idea to pay attention to what your specific needs are—size, shape, configuration—so you pick the right one. Also, staying updated on the latest advancements in AI and automation can really give you an edge by improving performance and efficiency. And don’t forget, regular maintenance and keeping an eye on things is key to making sure your hydrocyclone keeps doing its thing effectively.

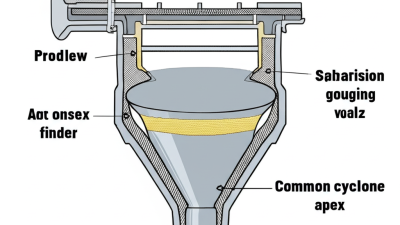

: A hydrocyclone separator is a device that uses centrifugal force to separate particles based on density, primarily used in industrial filtration processes to remove solids from liquids.

Hydrocyclone separators are primarily used in the oil and gas industry, as well as in agriculture and mining for effective filtration.

The global hydrocyclone market is projected to reach USD 600 million by 2027, driven by the demand for effective filtration methods and reducing operational downtime.

When selecting a hydrocyclone, consider factors such as flow rate, particle size, and specific gravity, as these can significantly impact filtration efficiency and cost-effectiveness.

Hydrocyclones can achieve impressive separation efficiencies, often exceeding 90%, depending on the application and design specifications.

Future trends indicate a shift towards automation and AI integration, which can enhance filtration processes, improve separation efficiency, and lead to significant cost savings.

AI technologies can optimize filtration processes using real-time data analytics, potentially raising productivity levels by 20-30% and enhancing operational efficiency.

Regular maintenance is crucial to prevent blockages and ensure consistent performance, optimizing the functioning of hydrocyclone separators over time.

Integrating hydrocyclones into filtration systems can enhance separation efficiency, significantly reducing waste generated and energy consumption in industrial processes.

Assess the specific application needs to choose the right size and configuration of hydrocyclones, stay updated on technological advancements, and ensure regular maintenance and monitoring for optimal functioning.

Hydrocyclone separators have really become a game-changer in industrial filtration. They’re pretty amazing at boosting efficiency and helping get more done in less time. Basically, they use centrifugal force to spin out solids from liquids — and honestly, they’re super versatile, working well across a bunch of different applications. If you get the hang of how hydrocyclones work and understand the science behind their filtering power, it’s much easier to implement them smoothly. Having a simple step-by-step guide can make the switch to using these systems a lot less daunting, and knowing the common hurdles along the way helps keep things running smoothly and efficiently.

Compared to old-school filtration methods, hydrocyclones are more efficient and cost less to maintain in the long run. As Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. keeps pushing forward with innovative cyclone tech, the future looks bright for these separators. They’re paving the way for better productivity—not just in oil and gas, but in a bunch of other industries too.