strict management, quality first, quality service, and customer satisfaction

You know, in the ever-changing world of industrial filtration, hydrocyclones really play a huge role — it's hard to overstate their importance. These nifty pieces of equipment use centrifugal force to separate out particles from liquids, which helps make a bunch of processes way more efficient, especially in the oil and gas industry. Here at Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd., we're always pushing to improve our hydrocyclone tech because we know each client’s needs are different. By shaking up the old-school filtration methods, hydrocyclones are not just making operations smoother and cheaper—they're also helping industries be a little kinder to the environment.

In this article, I’ll dig into how hydrocyclones are changing the game in filtration — talking about their design, how they work, and all the benefits they bring to industries that really need reliable separation and filtering tech.

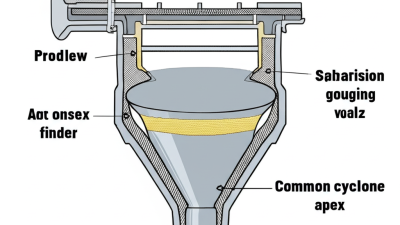

Hydrocyclones are pretty clever devices mainly used in industrial filtration—think of them as the filters that use spinning forces to separate out particles from liquids. The way they work is actually simple but effective: fluid gets introduced into the cyclone chamber at an angle, which causes it to spin in a spiral. As it twirls, a centrifugal force kicks in, pushing the heavier particles outward toward the walls, while the lighter stuff stays more in the center, eventually flowing out through the top. It's like a spin cycle, but for separating solids!

The overall performance of a hydrocyclone really depends on things like the speed of the fluid, how thick or sticky it is, and the size of the particles you're trying to filter out. When you crank up that centrifugal force, heavier particles settle faster, which means you can process more material faster and keep downtime to a minimum—bonus! And here's a nice little perk: since hydrocyclones don’t have any moving parts, they tend to be cheaper to operate and easier to maintain. From mining to wastewater cleanup, they’re pretty versatile. Getting a grip on how this filtration trick works can actually help us make industrial processes more efficient and better at managing resources. Pretty neat, right?

Hydrocyclones are really making waves in the world of industrial filtration these days. They've become quite a game-changer, especially when you compare them to the old-school methods. I read somewhere—like in a report by Global Market Insights—that the hydrocyclone market is expected to grow at about 5.6% each year between 2023 and 2030. That’s pretty impressive growth, and honestly, it makes sense when you think about what these devices can do. They’re great at separating solids from liquids without taking up lots of space or needing super complicated systems. They use centrifugal force—kind of like spinning things around—to get the job done. Plus, they can handle large volumes while using less energy, which saves a bunch on operational costs.

On the flip side, traditional filters like bag filters or screens tend to be more of a hassle—they need replacing parts pretty often and demand more maintenance. That often means more downtime and higher running costs. A study by the American Filtration Society even points out that hydrocyclones can filter out particles as tiny as 10 microns—way better than some membrane filters, which are only about 20% more efficient. That’s a big deal because it not only boosts productivity but also helps keep equipment in better shape longer by avoiding clogs and wear-and-tear that traditional setups often face. As industries search for filtration solutions that are both affordable and reliable, hydrocyclones are looking more and more like the smart choice.

Hydrocyclones have really become a game-changer in various industrial filtration processes—pretty much across the board, from mining to wastewater treatment. What’s cool about them is how effectively they can separate particles based on size and density—that efficiency is hard to beat. I read in a report from Frost & Sullivan that industries using hydrocyclones have managed to cut their operating costs by up to 30%. That’s a huge boost in productivity, no doubt. Take mining, for example: hydrocyclones help sort out valuable minerals from the waste, which means better yields and less environmental harm.

To get the most out of your hydrocyclones, it’s a good idea to keep the feed slurry well-mixed and pick the right cut size for your specific needs. Also, don’t forget regular maintenance—things like cleaning out blockages or worn parts can really keep performance steady.

In the oil and gas world, hydrocyclones are used to separate oil from water, and they often achieve oil recovery rates over 95%. That’s pretty impressive because it makes the whole process smoother and helps cut down on environmental issues—less oil spills, less wastewater to treat. Several case studies show that companies using these systems see a pretty quick return on their investment, which really shows just how much of a difference hydrocyclones can make in filtration systems.

Tip: keep an eye on the pressure drop across the cyclone. If you notice it changing a lot, it might mean wear or blockages—best to deal with it sooner rather than later to keep things running smoothly.

Hydrocyclones are really shaking things up in the world of industrial filtration. They've been shown to cut down costs pretty significantly, all while making processes more efficient. I came across a report from Global Market Insights that predicts the hydrocyclone market could hit over $550 million by 2026 — pretty impressive! The reason? These devices excel at separating and clarifying materials across a bunch of different industries. By using centrifugal forces, hydrocyclones can separate solids from liquids at rates up to 95%. That’s a big win—not only does it boost product quality, but it also cuts down on waste. Industries like mining and wastewater treatment benefit a lot because they can operate more cheaply without needing overly complicated or costly filtration systems, plus there's less maintenance hassle.

Hydrocyclones are really shaking things up in the world of industrial filtration. They've been shown to cut down costs pretty significantly, all while making processes more efficient. I came across a report from Global Market Insights that predicts the hydrocyclone market could hit over $550 million by 2026 — pretty impressive! The reason? These devices excel at separating and clarifying materials across a bunch of different industries. By using centrifugal forces, hydrocyclones can separate solids from liquids at rates up to 95%. That’s a big win—not only does it boost product quality, but it also cuts down on waste. Industries like mining and wastewater treatment benefit a lot because they can operate more cheaply without needing overly complicated or costly filtration systems, plus there's less maintenance hassle.

And honestly, the savings don’t stop there. According to a study by the American Society of Civil Engineers, tossing hydrocyclones into mining processes has helped cut operational costs by over 25% in some cases. That’s a pretty compelling reason to consider switching from traditional filters, which tend to eat up more energy and often need repairs or replacements more frequently. The quick return on investment makes it a no-brainer for many businesses. Plus, it helps them move closer to their sustainability goals by making smarter use of resources — all in all, it’s a win-win!

Lately, there’s been some pretty exciting progress in hydrocyclone technology, and it’s actually set to shake up how industries handle filtration. You’ve probably heard about the cool new collaboration between top companies working together to develop these innovative systems — it’s a big deal. One of the standout innovations is the MHC Hydrocyclone with a curved bottom (CB), which is really a game-changer when it comes to separating solids from liquids more effectively. Not only does this new design boost how well traditional filtration setups work, but it also lines up perfectly with the growing push for more sustainable and eco-friendly solutions across different sectors.

As the market for cyclone separators keeps growing—mainly because everyone’s really into clean energy and better waste management—it's pretty clear that future innovations will zero in on making these devices more efficient and adaptable. R&D efforts right now are all about mixing advanced materials and cool new designs to get even better filtration results without burning through tons of energy. All in all, these improvements really underscore how hydrocyclones are becoming super important for cleaner manufacturing processes and tackling the environmental issues tied to industrial waste. It’s an exciting time for anyone interested in greener, smarter tech!

: Hydrocyclones are used for solid-liquid separation in various industries, enhancing efficiency and reducing operational costs.

Hydrocyclones can separate solids from liquids at rates up to 95%, improving product quality and minimizing waste.

The hydrocyclone market is projected to surpass $550 million by 2026, driven by their superior separation capabilities.

Implementing hydrocyclones in mining processes has led to operational cost reductions of over 25% in some cases.

Hydrocyclones provide a more attractive alternative to traditional filtration methods, as they often incur lower energy consumption and less downtime.

Recent advancements include the introduction of the MHC Hydrocyclone Curved Bottom (CB), which enhances efficiency in solid-liquid separation.

The use of hydrocyclones optimizes resource usage and supports cleaner production processes, helping businesses achieve sustainability objectives.

Innovations are driven by the demand for sustainable and eco-friendly filtration solutions and the need for enhanced operational efficiency.

Advanced materials and cutting-edge designs are being developed to optimize filtration capabilities while minimizing energy consumption.

Hydrocyclones help in improving waste management processes by providing effective separation solutions that contribute to cleaner production practices.

Hydrocyclones are really shaking up how industries handle filtration these days, thanks to their unique way of separating stuff out. Basically, they use centrifugal force to quickly and efficiently remove particles from liquids, and they often beat traditional filters in both speed and effectiveness. What’s pretty great about them is their simplicity—plus, they don’t cost a fortune to run—which makes them a solid choice for all kinds of industries, like oil and gas, where getting rid of mixed-in solids is a big deal. There are plenty of success stories showing how they’ve helped boost productivity and cut down on costs.

As Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. keeps pushing the boundaries with new cyclone separation tech, the future looks promising. They’re working on even better, more efficient hydrocyclone designs that can meet the constantly changing needs of the industry. All these advancements mean hydrocyclones are becoming an even more essential part of modern filtration and separation systems, making operations smoother and more reliable.