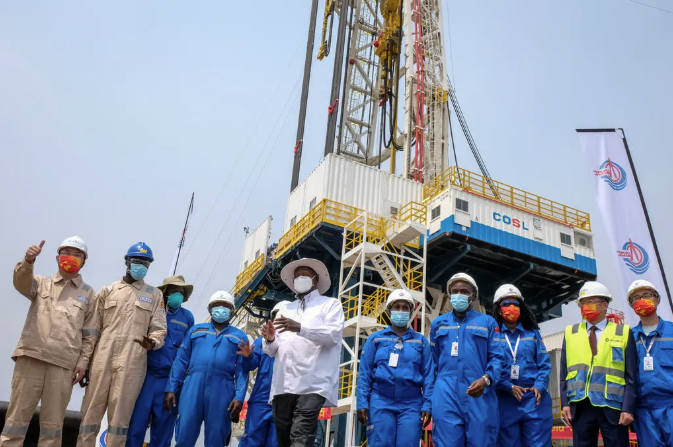

China’s “Three Oil Giants” began their large-scale entry into Africa as early as the 2000s and have now become significant players in the continent’s oil and gas sector.

China National Petroleum Corporation (CNPC)

Africa is one of the earliest regions where China National Petroleum Corporation (CNPC) expanded globally. Since 1995, CNPC has engaged in energy cooperation in Africa, establishing a distinctive partnership approach that differs significantly from the operational models of traditional Western oil companies. Its footprint spans over 20 countries and regions, including Chad, Niger, Mozambique, and Benin.

In Nigeria, CNPC participates in the exploration of multiple onshore and shallow-water blocks. In Niger, CNPC leads the development of the Agadem oil field and the construction of a crude oil pipeline spanning over 1,900 kilometers, securing a $400 million crude oil supply agreement in 2024. In Mozambique, CNPC holds a 20% stake in the Rovuma LNG project, one of the largest LNG projects in Africa.

CNPC’s technology exports focus primarily on pipeline construction and onshore oilfield development, with expertise in an integrated “oilfield + pipeline + refinery” model.

China Petrochemical Corporation (Sinopec)

In recent years, China Petrochemical Corporation (Sinopec) has actively engaged in cooperation across Africa in areas such as oil and gas resource investment, petroleum engineering technical services, refining and chemical engineering services, and energy trade. Sinopec focuses on engineering services and refining/petrochemicals, including undertaking and completing engineering design projects such as the 600,000 tons/year catalytic cracking unit at the N’Djamena Refinery in Chad, the expansion of the 5 million tons/year condensate processing unit and its storage and transportation facilities in Algeria, as well as technology export projects like the delayed coking project in Sudan. The company has also executed engineering, procurement, and construction (EPC) projects, such as the 200,000 tons/year methyl tert-butyl ether (MTBE) unit at the Arzew Refinery in Algeria, and has established extensive cooperative relationships with local clients.

In addition to engineering and refining, in 2013, Sinopec International Petroleum Exploration and Production Corporation (SIPC), a subsidiary of Sinopec, officially entered Egypt’s upstream and midstream oil and gas market by acquiring equity in the Apache project in Egypt.

China National Offshore Oil Corporation (CNOOC)

China National Offshore Oil Corporation (CNOOC) focuses on deepwater and offshore projects. In Nigeria, it holds a 45% stake in the OML130 block, which includes the development of the Egina ultra-deepwater oil field. This project utilizes an FPSO (Floating Production Storage and Offloading) vessel with a peak production capacity of 200,000 barrels per day. CNOOC has introduced China’s independently developed FPSO technology and subsea production systems. In Angola, CNOOC participates in multiple deepwater blocks. The company’s technology exports emphasize deepwater engineering and FPSO construction, and in recent years, it has been promoting Chinese-standard equipment in Africa.

The advantages of Chinese enterprises in Africa lie in their low costs, rapid execution, strong willingness to cooperate with local governments, and technological exports that include infrastructure construction and localized training. However, they also face challenges such as geopolitical risks and environmental compliance pressures. In recent years, Chinese companies have shifted from a “resources-for-infrastructure” approach to a greater emphasis on sustainable development and projects involving LNG and natural gas, forming complementary partnerships with international giants.

The extraction of oil and natural gas cannot be achieved without separation equipment.

Shanghai Shangjiang Petroleum Engineering Equipment Co., Ltd. established in Shanghai in 2016, is a modern technology enterprise integrating R&D, design, production, and service. We are dedicated to developing separation and filtration equipment for the oil, gas, and petrochemical industries. Our high-efficiency product portfolio includes de-oiling/dewatering hydrocyclones, desanders for micron-sized particles, and compact flotation units. We provide complete skid-mounted solutions and also offer third-party equipment retrofitting and after-sales services. Holding multiple proprietary patents and operating under a DNV-GL certified ISO-9001, ISO-14001, and ISO-45001 management system, we deliver optimized process solutions, precise product design, strict adherence to engineering specifications, and ongoing operational support.

Our high-efficiency cyclone desanders, renowned for their exceptional 98% separation rate, have earned recognition from international energy leaders. Constructed with advanced wear-resistant ceramics, these units achieve 98% removal of particles as fine as 0.5 microns in gas streams. This capability enables the reinjection of produced gas for miscible flooding in low-permeability reservoirs, a key solution for enhancing oil recovery in challenging formations. Alternatively, they can treat produced water, removing 98% of particles larger than 2 microns for direct reinjection, thereby boosting water-flood efficiency while minimizing environmental impact.

Our new product——The High Efficiency Ultra-Fine Particle Desander is a liquid-solid separation device that utilizes an efficient centrifugal principle to separate suspended impurities—such as solids in produced water, seawater, condensate, fine particles in high-viscosity liquids, and catalyst powder in reactors—from fluids (liquids, gases, or gas-liquid mixtures). It effectively removes solid particles with sizes down to 2 microns (at 98% efficiency) or smaller.

The High Efficiency Ultra-Fine Particle Desander delivers high sand removal efficiency, capable of removing solid particles down to 2 microns. The equipment features a compact footprint, requires no external power or chemical additives, and has a service life of approximately 20 years. It offers online sand discharge capability without the need for production shutdown.

Proven in major global fields operated by CNOOC, CNPC, Petronas, and others across Southeast Asia, SJPEE desanders are deployed on wellhead and production platforms. They provide reliable solids removal from gas, well fluids, and condensate, and are critical for seawater purification, production stream protection, and water injection/flooding programs.

Beyond desanders, SJPEE offers a portfolio of acclaimed separation technologies. Our product line includes membrane systems for natural gas CO₂ removal, deoiling hydrocyclones, high-performance compact flotation units (CFUs), shale gas desanding,Cyclonic dewater package with produced water treatment,and multi-chamber hydrocyclones, delivering comprehensive solutions for the industry’s toughest challenges.

Post time: Feb-10-2026