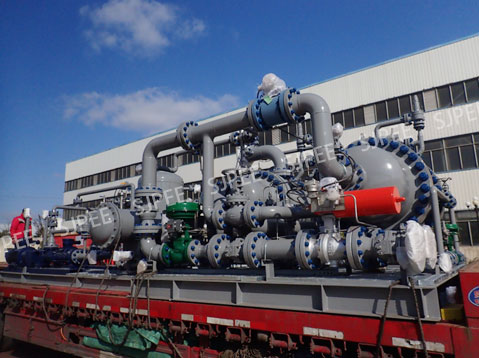

Product Show

Technical Parameters

| Product Name |

Hydrocyclone |

||

| Material | A516-70N | Delivery Time | 12 weeks |

| Capacity (M3/hr) | 5000 | Inlet Pressure (MPag) | 1.2 |

| Size | 5.7m x 2.6m x 1.9m | Place of Origin | China |

| Weight(kg) | 11000 | Packing | standard package |

| MOQ | 1 pc | Warranty period | 1 year |

Brand

SJPEE

Module

Customized according to client requirements

Application

Oil & Gas / Offshore Oil Fields / Onshore Oil Fields

Product Description

Precision Separation: 50% removal rate for 7-micron particles

Authoritative Certification: ISO-certified by DNV/GL, compliant with NACE anti-corrosion standards

Durability: Duplex stainless steel construction, wear-resistant, anti-corrosion and anti-clogging design

Convenience & Efficiency: Easy installation, simple operation and maintenance, long service life

Hydrocyclones are commonly used oil-water separation equipment in oilfields. By utilizing the powerful centrifugal force generated by a pressure drop, the device creates a high-speed swirling effect within the cyclonic tube. Due to the difference in fluid densities, lighter oil particles are forced toward the center, while heavier components are pushed against the inner wall of the tube. This enables centrifugal liquid-liquid separation, achieving the goal of oil-water separation.

Typically, these vessels are designed based on the maximum flow rate. However, when the flow rate in the production system varies significantly, exceeding the flexibility range of conventional hydrocyclones, their performance can be compromised.

The multi-chamber hydrocyclone addresses this issue by dividing the vessel into two to four chambers. A set of valves allows for multiple flow load configurations, thereby achieving highly flexible operation and ensuring the equipment consistently maintains optimal working conditions.

The hydrocyclone adopts a pressure vessel design, equipped with specialized hydrocyclone liners (MF-20 Model). It utilizes centrifugal force generated by a swirling vortex to separate free oil particles from liquids (such as produced water). This product features compact size, simple structure, and user-friendly operation, making it suitable for various working conditions. It can be used either as a standalone unit or integrated with other equipment (such as flotation units, coalescing separators, degassing tanks, and ultra-fine solid separators) to form a complete produced water treatment and reinjection system. Advantages include high volumetric processing capacity with a small footprint, high classification efficiency (up to 80%–98%), exceptional operational flexibility (handling flow ratios of 1:100 or higher), low operating costs, and extended service life.

Post time: Oct-28-2025